High Cpu Plc Usage – Causes, Solutions, and Optimization Tips!

High CPU usage in PLCs can cause performance issues, but optimizing code, prioritizing tasks, and improving communication efficiency can help reduce consumption and boost performance.

This article will explore the causes of high CPU usage in PLCs, its impact on operations, and effective strategies to optimize and reduce CPU consumption.

Table of Contents

What is PLC CPU Usage?

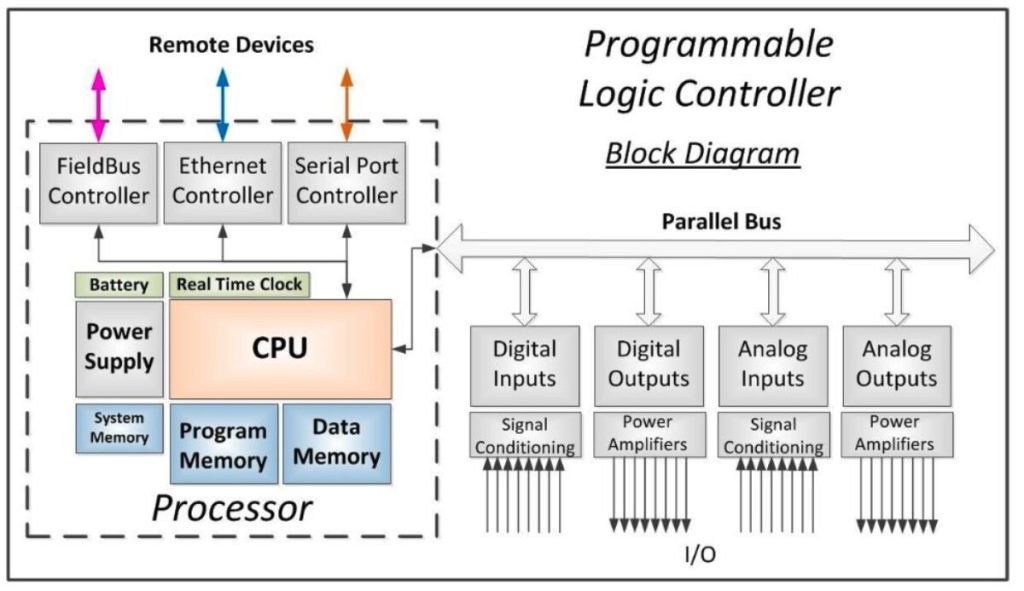

A Programmable Logic Controller (PLC) is a robust, industrial digital computer designed for automating various electromechanical processes. Like any computer, a PLC has a CPU (Central Processing Unit) that executes instructions, processes data, and controls input/output devices.

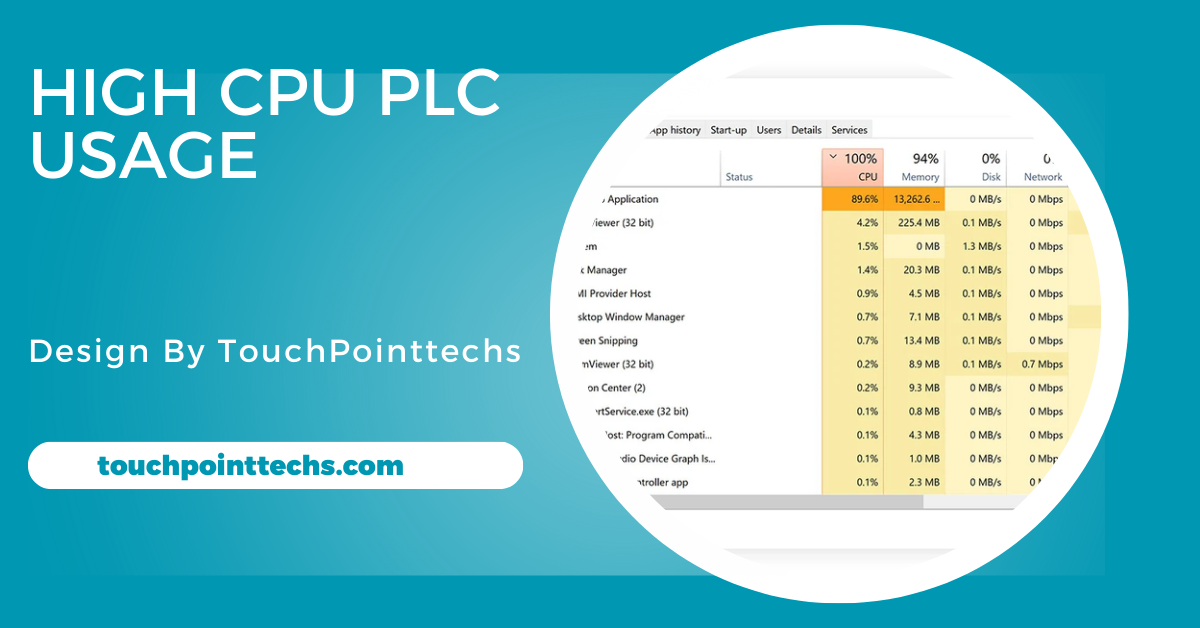

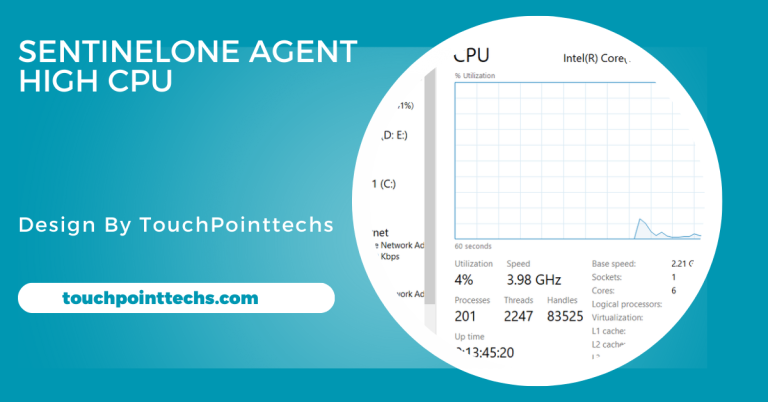

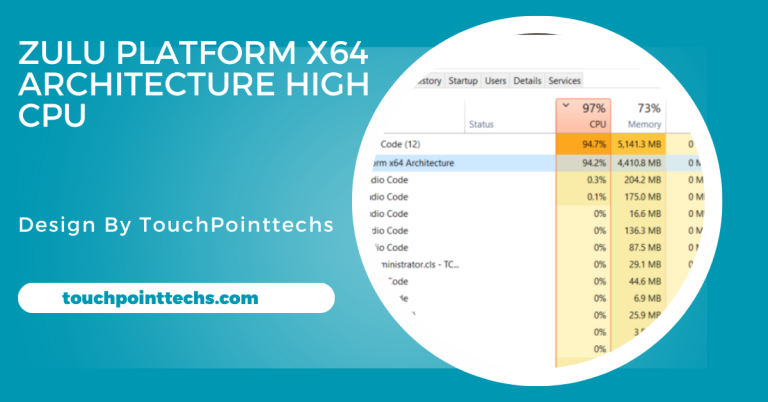

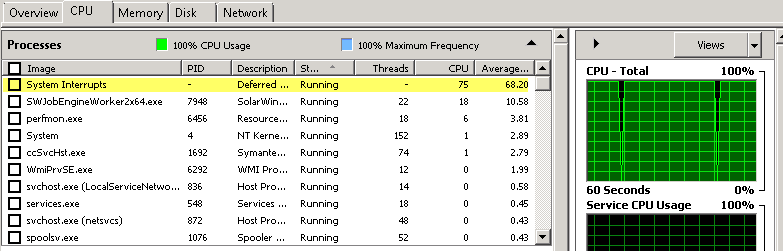

CPU usage refers to the percentage of the CPU’s capacity being utilized by the system at any given time. High CPU usage indicates that the system is operating close to its maximum capacity, which can result in slower response times and potential system overload.

Common Causes of High CPU Usage in PLCs:

- Complex Programs and Inefficient Code: One of the most common causes of high CPU usage in PLCs is poorly optimized or overly complex code. Long scan times caused by excessive or unnecessary instructions can increase CPU load. For example, frequent use of loops, unnecessary timers, or continuous polling of data can quickly consume CPU resources.

- High-Frequency Task Execution: PLCs typically handle multiple tasks with varying priority levels. High-priority tasks executed at very short intervals (like every millisecond) can hog CPU resources, leaving little room for other tasks.

- Large Data Handling: Managing large amounts of data or complex mathematical calculations can significantly increase CPU load. If the PLC is continuously processing extensive data sets, the CPU may struggle to keep up, leading to high usage.

- Communication Overload: PLCs often communicate with other systems via Ethernet, Modbus, or other communication protocols. Excessive communication requests or poor network design can result in higher CPU consumption as the PLC struggles to manage incoming and outgoing data.

- I/O Overload: If the PLC is controlling or monitoring a large number of input/output (I/O) devices, this can add strain to the CPU. Processing real-time data from numerous sensors, motors, and actuators without efficient optimization can lead to higher CPU usage.

How High CPU Usage Affects PLC Performance:

High CPU usage can lead to several adverse effects on the overall performance of a PLC:

- Increased Scan Time: When the CPU is overloaded, the PLC’s scan cycle (the time it takes to read inputs, execute logic, and update outputs) becomes longer, slowing down response times.

- Task Delays: Tasks with lower priority may be delayed or skipped entirely, leading to unexpected system behavior.

- System Instability: Prolonged high CPU usage can cause system instability or even crashes, jeopardizing production lines or critical processes.

- Limited Scalability: High CPU usage limits the capacity to add more functionality, such as new sensors or expanded logic, to the PLC program.

How to Optimize and Reduce CPU Usage in PLCs:

- Code Optimization: Efficient programming can drastically reduce CPU load. Simplify complex logic, avoid unnecessary looping structures, and ensure that tasks only run when needed. This will not only reduce CPU usage but also improve scan time and system responsiveness.

- Task Prioritization: Analyze and prioritize tasks according to their importance. Ensure that critical tasks are given enough CPU bandwidth, while less important or infrequent tasks are scheduled less often. This will free up CPU resources for essential processes.

- Modular Programming: Divide complex programs into smaller, manageable subprograms or modules. This allows the CPU to process each part more efficiently rather than handling a single large program.

- Optimized Data Handling: Minimize the amount of data being processed at once. Filter out unnecessary data and only process essential information. For complex calculations, consider offloading some tasks to external systems or devices.

- Communication Efficiency: Streamline communication protocols to ensure that the PLC isn’t overwhelmed by unnecessary or redundant data requests. Consider using event-driven communication rather than continuous polling to reduce load on the CPU.

- I/O Management: Reduce the frequency of I/O updates when real-time monitoring isn’t necessary. Group I/O devices in logical clusters and update them only when changes are detected.

- Regular Monitoring and Diagnostics: Continuously monitor CPU usage via diagnostic tools provided by the PLC software. This will help identify areas where optimization is needed. Regular diagnostics also ensure that any sudden spikes in CPU usage are quickly addressed before causing a system failure.

When to Upgrade Your PLC:

In some cases, even with optimizations, the CPU usage may remain persistently high due to the demands of the system. If the current PLC is unable to handle the increasing complexity of automation tasks, it may be time to upgrade to a more powerful model with higher CPU capacity.

Key signs that an upgrade is necessary include:

- Consistent Overloading: If CPU usage is consistently near 100% and causing performance issues, an upgrade may be required.

- Limited Expansion: If you’re unable to add more devices, sensors, or functionality due to high CPU usage, upgrading to a higher-capacity PLC can provide the necessary headroom.

- Obsolete Hardware: Older PLC models may not be optimized for modern tasks and may struggle with new automation demands. Upgrading to a newer model will bring better performance and efficiency.

FAQ’s

1. What causes high CPU usage in PLCs?

High CPU usage in PLCs is often caused by complex programs, inefficient code, high-frequency tasks, large data handling, communication overload, and excessive I/O operations.

2. How does high CPU usage affect PLC performance?

High CPU usage can increase scan time, cause task delays, lead to system instability, and limit the scalability of the PLC.

3. How can I reduce CPU usage in my PLC?

You can reduce CPU usage by optimizing code, prioritizing tasks, managing data efficiently, improving communication protocols, and reducing unnecessary I/O updates.

4. When should I consider upgrading my PLC due to high CPU usage?

Consider upgrading when CPU usage is consistently near 100%, limiting system expansion, or when the PLC hardware becomes outdated and unable to meet modern automation demands.

5. What tools can help monitor CPU usage in a PLC?

Diagnostic tools provided by the PLC software can continuously monitor CPU usage, helping identify areas for optimization and preventing system failures.

Conclusion

High CPU usage in PLCs is a critical issue that can disrupt industrial processes and reduce efficiency. By understanding the causes of high CPU usage and implementing effective optimization techniques, you can improve the performance, reliability, and scalability of your PLC systems. Regular monitoring and diagnostic checks, along with code and communication optimizations, will ensure that your PLC runs smoothly and meets the demands of modern automation tasks.