Plc High Cpu Usage – A Detailed Overview!

PLC high CPU usage occurs when the processor is overloaded, leading to delays and inefficiencies, but can be managed through optimized programming and hardware improvements.

In this comprehensive guide, we will examine what high CPU usage means for a PLC, explore the primary causes, highlight potential impacts, and outline practical solutions to manage and reduce CPU load effectively.

Table of Contents

What is PLC High CPU Usage?

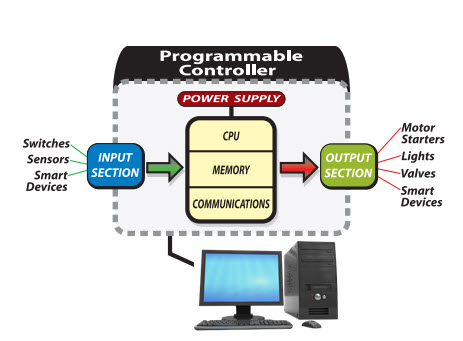

High CPU usage in a PLC occurs when the processor is operating at or near its maximum capacity for extended periods of time. The CPU in a PLC is responsible for executing control instructions, managing communication with external devices, performing calculations, and regulating real-time processes. When the CPU is overloaded, it can struggle to complete these tasks efficiently, leading to slowdowns, delays, or even system crashes.

To ensure the smooth operation of a PLC-based system, it’s essential to keep CPU usage at a manageable level. High CPU usage can occur during heavy process loads, complex control scenarios, or due to programming inefficiencies.

Causes of High CPU Usage in PLCs:

Complex Programming Logic:

The complexity of the PLC’s control logic plays a significant role in determining CPU usage. If a PLC is running complex or inefficiently written code, such as deep nested loops, excessive calculations, or too many conditional checks, the CPU has to work harder to execute these tasks. For example, in ladder logic or function block diagrams, an overcomplicated sequence of operations can push the CPU to its limits.

Extended Scan Cycle Time:

Every PLC operates on a scan cycle, which includes reading inputs, executing the control program, and updating outputs. A long scan cycle can cause high CPU usage, especially if the cycle time is affected by inefficient programming or too many tasks being handled in one scan. Extended scan times often occur when the PLC is asked to handle more tasks than it was originally designed for.

Excessive Communication Load:

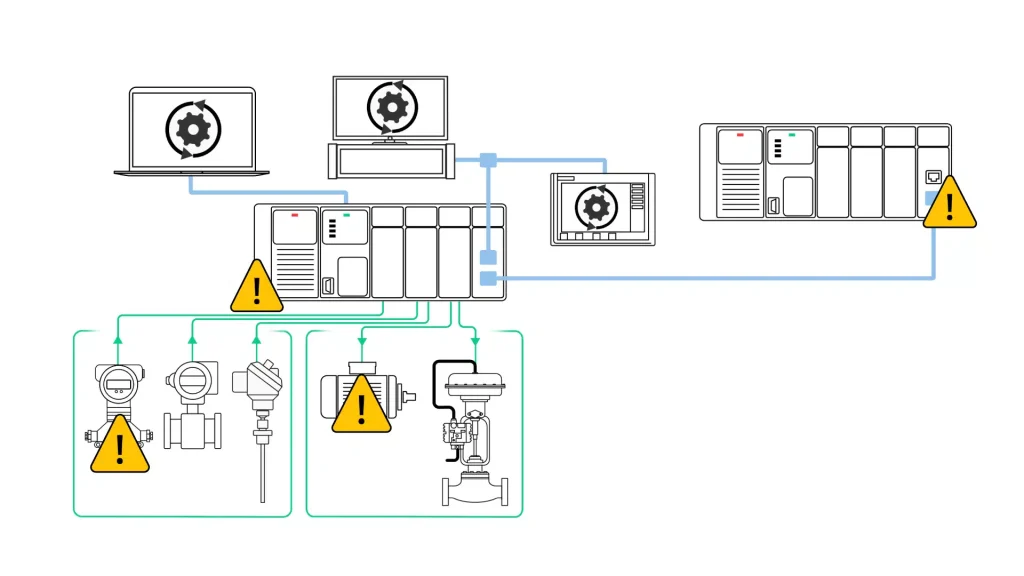

PLCs often communicate with other systems, such as Human Machine Interfaces (HMIs), Supervisory Control and Data Acquisition (SCADA) systems, and other PLCs over networks.

Excessive communication demands, especially when using resource-heavy communication protocols or frequently polling devices, can lead to high CPU usage. The more data that the PLC is required to process and transmit, the higher the strain on its CPU.

Intensive Data Logging and Processing:

Modern PLCs often log operational data for analysis and tracking purposes. While useful, continuous or real-time data logging can heavily tax the CPU, especially when large datasets are involved.

Additionally, if the PLC is required to process or analyze this data on the fly, such as performing complex calculations or filtering, it increases CPU load.

Also Read: Is 4000Rpm Too Low For Cpu Fan – A Comprehensive Guide to Optimizing Fan Speeds!

Handling Multiple External Devices:

Many PLCs are connected to external devices like sensors, actuators, and I/O modules. The more devices that are connected to the PLC, the more processing power is needed to handle the input/output operations. When multiple devices are sending data simultaneously or require frequent updates, this can result in high CPU usage.

Firmware or Software Bugs:

Outdated or malfunctioning firmware can lead to inefficient CPU usage. Bugs or inefficiencies in the operating software of the PLC can result in processes taking longer to complete, thereby increasing CPU load. It’s essential to ensure that the firmware and software are regularly updated to avoid such issues.

Use of High-Frequency Tasks:

PLCs are sometimes programmed to handle tasks at high frequencies (such as reading inputs or controlling outputs multiple times per second). While this may be necessary for some processes, it can lead to an increased CPU burden, especially if the tasks are not spread out effectively across scan cycles.

Impacts of High CPU Usage on PLC Systems:

Delayed or Missed Control Actions:

A PLC under heavy CPU load may not be able to process control instructions in real-time, leading to delays. This can cause slow system responses, where critical processes may be delayed or missed altogether. In industries where precision and timing are critical, such as in manufacturing or chemical processing, this can result in product defects or even hazardous situations.

System Overloads and Crashes:

High CPU usage over an extended period can lead to system overloads, where the PLC’s CPU fails to manage all tasks effectively. In extreme cases, this can cause the system to crash, leading to unplanned downtime. Recovering from such crashes not only affects productivity but also requires technical expertise to troubleshoot and resolve.

Inaccurate Data Logging and Monitoring:

PLCs that are handling too many tasks at once might struggle to log data accurately or monitor processes effectively. Incomplete or incorrect data can lead to flawed analysis, which might result in improper decision-making regarding system performance and maintenance.

Increased Energy Consumption:

As the PLC’s CPU works harder to process more tasks, it consumes more energy. This can lead to higher operational costs and potentially overheating if cooling systems are inadequate, further exacerbating system inefficiency.

Solutions to Reduce and Manage PLC High CPU Usage:

Optimize Control Logic:

Regularly review the PLC program and simplify complex routines where possible. Eliminate unnecessary loops, redundant calculations, and excessive data handling to reduce CPU load. Structured, modular programming can also help in breaking down tasks into manageable pieces, improving execution efficiency.

Reduce Scan Cycle Time:

To improve CPU efficiency, limit the number of tasks that need to be completed during each scan cycle. Splitting tasks across multiple cycles or adjusting the scan time in the PLC settings can reduce CPU strain and keep the system running smoothly.

Streamline Communication Protocols:

Evaluate the communication protocols in use. Ensure that data transfer rates are appropriate and not excessive for the task at hand. Optimizing communication with external devices, such as HMIs or SCADA systems, can significantly reduce CPU load. Using optimized protocols such as Ethernet/IP or Modbus TCP/IP can streamline communication and reduce CPU workload.

Offload Data Logging to External Devices:

Instead of relying solely on the PLC for data logging, offload this task to external storage devices or dedicated data logging systems. This will free up CPU resources for more critical control functions and ensure smoother operation.

Upgrade to More Powerful Hardware:

If the current PLC is consistently struggling with high CPU usage, it may be time to upgrade to a more powerful model. Many modern PLCs are built with more advanced CPUs that can handle larger workloads and more complex tasks without becoming overloaded.

Use of External Controllers for Intensive Tasks:

Offload complex calculations or control loops to dedicated controllers or edge computing devices. This allows the PLC to focus on core control tasks while other devices handle the more CPU-intensive operations.

Regular Firmware and Software Updates:

Ensure that your PLC’s firmware and software are up-to-date. Many manufacturers release patches and updates that address bugs and improve performance, which can help reduce CPU load over time.

Also Read: What Cpu Does The Omen 25l Gt15 1075t Have Spec – A Detailed Overview!

Monitor CPU Usage Regularly:

Most modern PLC systems offer tools for monitoring CPU usage. Regularly checking CPU performance can help detect potential problems early and provide insight into which tasks are causing strain on the CPU. Making adjustments based on these insights can prevent overloads and ensure system efficiency.

FAQ’s

1. What causes high CPU usage in a PLC?

High CPU usage is caused by complex programming logic, extended scan cycles, excessive communication load, intensive data processing, and outdated firmware.

2. How does high CPU usage affect PLC performance?

It can cause delays, missed control actions, system overloads, crashes, and inaccurate data logging, leading to inefficiencies and unplanned downtime.

3. Can updating firmware help reduce CPU usage in a PLC?

Yes, regular firmware and software updates can fix bugs, improve performance, and reduce CPU load.

4. What is the role of scan cycle time in CPU usage?

A long scan cycle due to inefficient programming or task overload increases CPU usage and slows down system responses.

5. What solutions can reduce high CPU usage in a PLC?

Optimizing control logic, reducing scan cycle time, streamlining communication protocols, offloading data logging, and upgrading hardware are effective solutions.

Conclusion

High CPU usage in a PLC can cause system slowdowns, crashes, and unplanned downtime. Identifying causes like complex programming, excessive communication, or intensive data logging helps users optimize performance. By implementing solutions such as code optimization, hardware upgrades, or task offloading, you can maintain system efficiency and prevent potential issues.